SAP IBP FOR RESPONSE & SUPPLY

IMPORTANCE OF RESPONSE & SUPPLY PLANNING

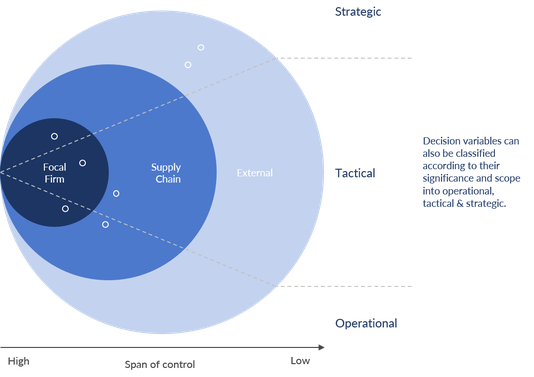

The pace of decision making in supply chains is quickening by the day. In other words, supply chains are operating at increasingly faster clock speeds. Not only that, in this digital economy where digital technologies are enabling ever increasing levels of customer intimacy, more and more decision variables are needed to be factored in for planning (in the picture on the right, this refers to variables beyond just the focal firm).

The implications are the increasing complexity of planning and also the shortening of the validity of plans made - that is, the shelf-life of plans are decreasing rapidly.

In this context, it is important for a successful planning tool to not only have the ability to model relevant supply chain variables to generate a feasible plan, but also provide tight integration with execution aspects and re-planning capabilities so that plans can be adjusted as they come in contact with reality. This aspect is extremely important in today's volatile environment where reality as imagined when plans were made could look very different from what it is when they are operationalized.

SAP IBP's Supply & Response is a tool that is up for this task: its unconstrained and constrained planning algorithms (supply part) provide support for mid- to long-term supply planning and its respond capabilities enable supply chains to manage uncertainty by providing tools needed to respond in line with business objectives when there are mismatches between planning assumptions and reality.

SOME KEY TRENDS AND CHALLENGES IN RESPONSE & SUPPLY PLANNING

- Increasing volatility and uncertainty: Ability to respond profitably to unanticipated situations

- Increasing complexity: Ability to model all relevant decision variables to generate as close to feasible a plan as possible

- New IBP process paradigm: "Integration" across organizations requires strong scenario planning and collaboration capabilities

- Blurring boundaries between planning and execution: Agile capabilities to keep up with the pace of change - tight integration between planning and execution

OVERVIEW OF SOME KEY CAPABILITIES of SAP IBP FOR RESPONSE & SUPPLY

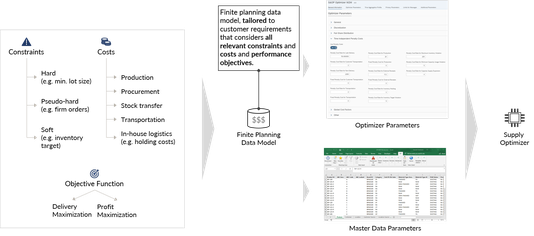

CONSTRAINED PLANNING: GENERATION OF A FEASIBLE PLAN

There are essentially two modes of supply planning in IBP: unconstrained and constrained. Unconstrained planning, as the name suggests, involves generating a plan that does not consider restrictions such as available capacity in terms of production, storage, raw materials etc. On the other hand, constrained planning involves modelling of relevant constraints (e.g. capacity), a cost model (including penalties and such) and an objective function (profit maximization, non-delivery minimization). IBP's Mixed Integer Linear Programming based optimization algorithms greatly facilitate creation of a close to feasible plan that can be reviewed and further adapted. Such an optimizer based plan is typically useful in the medium-term horizon and can serve as a solid first input for response planning.

SHORT-TERM RESPONSE PLANNING

Operational planning typically involves accounting for uncertainty by adapting plans by considering ground realities - for example, machine breakdowns leading lower than planned output or sales orders that are different from forecasted demands etc. IBP's response planning capabilities offers features that enable a profitable response in the face of volatility. Response allows modelling of rules that guide allocation of demands in a constrained situation. It also includes the functionality of order confirmations that helps enforce planning by considering allocations to then generate order promises against customer orders.

SCENARIO PLANNING AND WHAT-IF ANALYSES

The scope of planning in today's supply chains typically span multiple functions and organizations. What is also increasingly true is that such a collaborative process of generating plans needs to account for great uncertainty and therefore needs to be agile - that is, the scope is "agile inter-company" [1]. In order to collaborate and do so at speed requires capabilities like rapid scenario planning and what-if analyses powered by a single source of truth - something IBP provides. The illustration on the right shows one such example where a high growth scenario created in demand can subsequently be analysed in light of available capacity in supply and be presented to management for review and decision making - all of these activities can happen online (without leaving IBP).

[1] Chopra S, Meindl P (2016) Supply chain management: Strategy, planning, and operation / Sunil Chopra, Kellogg School of Management, Peter Meindl, Kepos Capital, Sixth edition, Global edition. Pearson, Boston