SAP IBP FOR DEMAND

IMPORTANCE OF ACCURATE DEMAND PLANNING

Demand forecasting lays the foundation for further planning the logistics and inventory. Without an accurate demand planning process in place enterprises can never attain efficiency in production planning, supply planning, inventory planning or execution.

Demand planning uses statistical approach that examine historical sales data, customer orders and current demand signals so as to predict demand patterns which enables firms to make smart decisions about inventory and production levels.

SOME KEY TRENDS AND CHALLENGES IN DEMAND PLANNING

- Rapid innovation: Need for effective New Product Introductions

- Focus on automation: Need for superior statistical forecasting capabilities

- Demanding customers: Superior sense and respond capabilities

- Orchestrating or shaping demand: Effective promotions management

SAP IBP FOR DEMAND: OVERVIEW OF SOME KEY CAPABILITIES

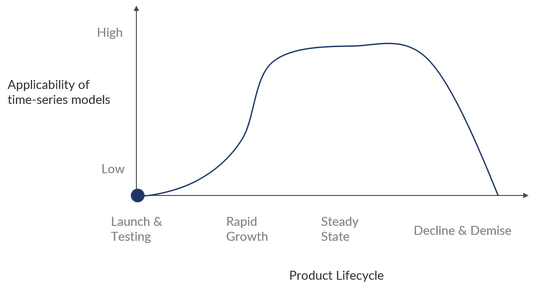

PHASE-IN FOR NEW PRODUCTS & PHASE-OUT OF OLD PRODUCTS

SAP IBP provides an application called ‘Manage Product Life Cycle’. Sales history can be simulated with respect to one or more than one product having similar demands.

Phase-In and Phase-Out curves can be generated (based on preset functions such as linear, superlinear, sublinear or a custom function) and implemented to model ramp-up and ramp-down of demands during phase-in and phase-out stages respectively of a product.

BETTER FORECAST ACCURACY

IBP follows a systematic approach to improve the forecast accuracy starting from ‘Data cleansing’ to ‘Demand sensing’ and adjustments.

First, sales history is cleansed from unwanted noises like past promotions & data errors. Based upon the cleansed data, statistical forecasting uses various sophisticated algorithms. These algorithms have capability to detect trends, seasonality and predict the demand for the future accordingly.

IBP also senses recent change in demand pattern and notifies new forecast accordingly.

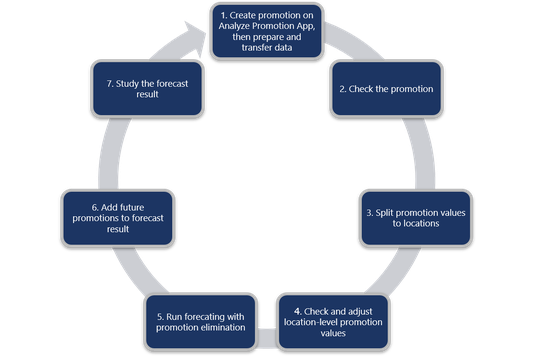

PROMOTION PLANNING

IBP is tightly integrated with promotional planning systems like ERP, CRM, TPM to incorporate promotion planning and uplift demand easily.

IBP’s fast data processing capability allows to transform dissimilar base plan level of promotional plan to Supply chain’s Product-Customer based planning.

IBP’s Promotion Analysis Application allows to analyze the promotional forecast results.