SAP IBP FOR Inventory

IMPORTANCE OF ACCURATE INVENTORY MANAGEMENT

Inventory management is about using inventory as the mediator to strike a balance between inventory investment and customer service level.

Ineffective inventory management paves the way for excess inventory or inadequate inventory (both symptoms of wrong planning). Excess inventory negatively impacts inventory turns (eventually impacting operating margin) whereas shortages result in unmet expectations and low customer service levels (eventually impacting sales revenues) - the cause-effect relationships are depicted in the graphic on the right. Generally, wrong planning causes inefficiencies that ultimately impact a firm's viability and competitiveness.

That’s why companies should focus on inventory management as a means to right-size inventory. As lengthening of supply chains in recent times has increased the importance of the positioning of inventory (not just quantity), IBP's Multi Echelon Inventory Optimization (MEIO) is uniquely positioned to address this challenge as its algorithms consider the dual dimensions of quantity and location (or positioning) of inventory simultaneously.

SOME KEY TRENDS AND CHALLENGES IN INVENTORY MANAGEMENT

- Elongated supply chains: Need for factoring long lead times

- Demanding customers: High service level targets

- High rate of innovation: Long tail, product proliferation

- Omnichannel: seamless experience across channels - Inventory redundancies

OVERVIEW OF SOME KEY CAPABILITIES of SAP IBP FOR INVENTORY

MULTI-ECHELON INVENTORY CALCULATIONS

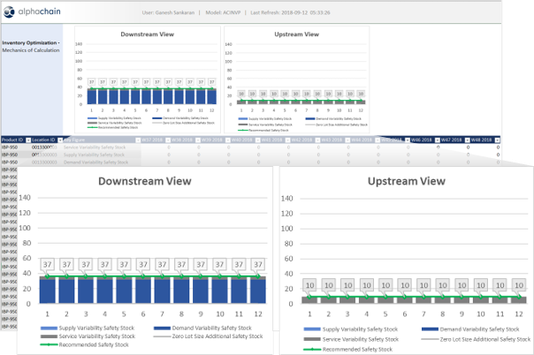

SAP IBP provides Global (Multi-Echelon) Inventory Optimization operator to calculate recommended safety stocks across all products and locations of the supply chain.

IBP's algorithm simultaneously considers key demand-side (demand volatility, service level targets) and supply-side (supply variability, service variability, replenishment frequency, lot sizes) factors and constraints and determines the location and quantity of safety stocks to enable the supply chain to optimally meet customer expectations whilst optimizing working capital.

RAPID INFORMATION FLOW & VISIBILITY

Monitoring inventory levels at real-time is crucial to effective inventory management and for taking prompt actions in case of unavailability/surpluses.

Transparent, rapid information flow between organizational functions regarding demand forecast, safety stock, inventory availability, customer service levels, costs on one platform is enabled through Analytics, Dashboards and Collaboration (via SAP JAM functionality).

WHAT-IF SCENARIO PLANNING & SIMULATION

The inventory planner can change the input parameters to see how recommended safety stock and thus working capital is affected since the purpose of IBP for Inventory is to optimize the efficiency of inventory and working capital throughout the supply chain.

With what-if analyses, potential benefits and improvement opportunities could be discovered and disruptions could be handled by adjusting inventory plans. The findings may require collaboration of different functions (production, procurement, logistics, sales, etc.) & senior management decisions, which is made possible through IBP's collaboration features powered by JAM.